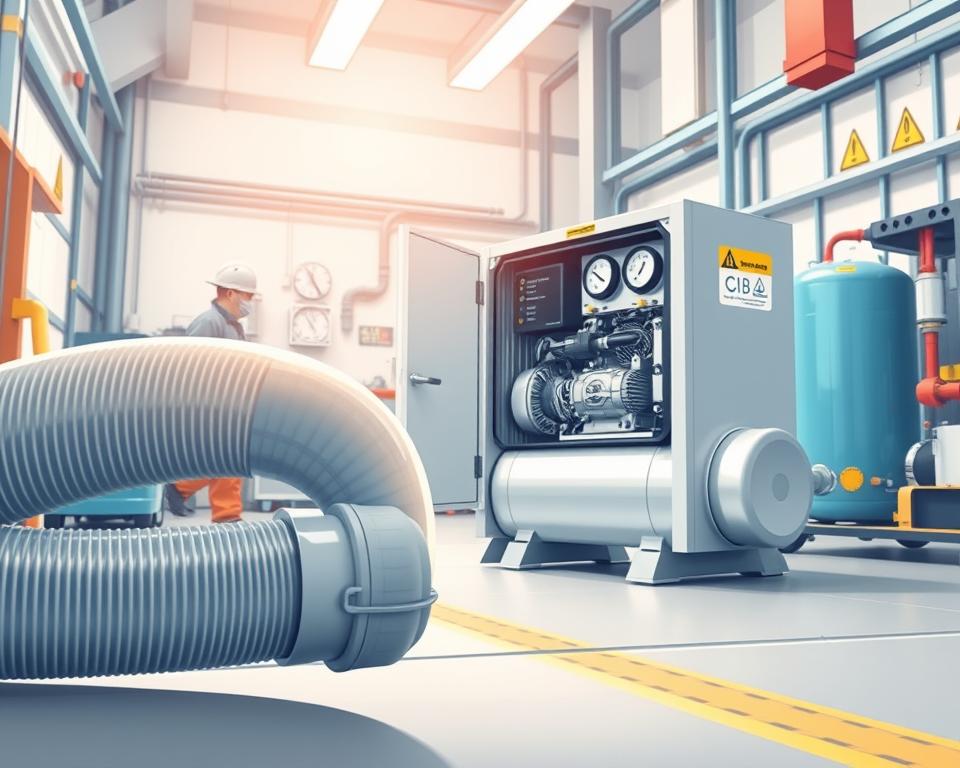

Your Complete Guide to PVC Pipe in Compressed Air Systems

A burst compressed air line can discharge energy comparable to a stick of dynamite—did you know? Many facilities still use piping systems made from risky materials, unaware of the dangers. Here’s why you must prioritize safety over cost when selecting PVC air line.

Even as interest rises, OSHA bans these materials for above-ground compressed air. Over time, exposure to oils and temperature changes weakens them, leading to catastrophic failures. Safe-rated pressures can still result in deadly bursts.

Installation Parts Supply provides safer options such as aluminum piping. Using approved materials saves you from fines and enhances safety. Discover steps to construct a secure system.

Central Ideas

- OSHA bans certain materials due to explosion risks.

- Heat and cold swings slashes claimed pressure capacity.

- Material becomes brittle with age, upping rupture chances.

- Aluminum lines deliver a far safer option.

- Proper investment prevents costly fines and accidents.

The Risks of PVC in Air Compressor Lines

PVC makers caution never to employ it in high-pressure air setups. Unlike water, compressed air stores explosive energy—a ruptured line can release force comparable to dynamite. This makes material choice critical for safety.

- Brittleness: Sub-freezing temperatures turn materials brittle, increasing fracture risks.

- Adhesive failures: Temperature changes and oils cause adhesive joints to fail.

- Misleading ratings: Most shops run above 110°F, slashing rated pressure in two.

A facility faced a $110k penalty when PVC shattered and harmed employees. The “heat of compression” further reduces safe operating limits, a factor often overlooked in ratings.

“Above-ground use of certain plastics for compressed air violates OSHA standards due to explosion risks.”

Steel and aluminum curve under stress instead of shattering. PVC shards fly far and fast, causing collateral damage.

Workshops face daily temperature fluctuations that accelerate material degradation. UV light and solvents over time sap pipe strength, triggering dangerous failures.

Recommended Piping Materials for Compressed Air

Modern aluminum systems beat old-school piping on both safety and performance. They leak 90% less than black iron, making them ideal for today’s shops. Aluminum’s lightness and anti-rust traits prolong system life.

Threadless modular aluminum assemblies speed assembly. Installation Parts Supply stocks ready-to-snap aluminum modules. A car plant saw a 40% drop in labor expenses after aluminum installation.

- Copper: Best for cleanrooms due to natural antimicrobial properties. Requires soldering expertise.

- Stainless Steel: Resists rust in humid areas like coastal workshops.

- ABS/HDPE: Plastic choices like ABS or HDPE handle harsh chemicals.

“Our aluminum retrofit reduced energy waste by 15%—paying for itself in 18 months.”

Torque matters. Over-tightened fittings crack, while loose ones leak. Aluminum fittings generally torque to 25–30 ft-lbs—follow the guide.

For food-grade applications, NSF-certified options ensure air purity. Pick piping suited to your facility’s conditions.

How to Choose the Right Piping Material for Your Needs

Balance budget, safety, and performance when choosing pipe. A Midwest factory saved $12,000 annually by switching to leak-resistant aluminum. Here’s how to make the right choice.

| Material | Cost (per ft) | Maintenance | ROI Time |

|---|---|---|---|

| Aluminum | $8.50 | Low | 18 months |

| Black Pipe | $5.00 | High | N/A |

| Copper | $10.20 | Medium | 24 months |

Temperature matters. From arctic chills to high heat, aluminum outperforms. Use stainless steel where solvents are present.

Pro Tip: Use leak-loss math to estimate ROI. A 10% air leak in 50 HP equals about $3,500 annually.

- Ensure your pipe PSI rating exceeds system pressure.

- Verify your system meets OSHA welding and pressure-test rules.

- Request a free system audit from Installation Parts Supply.

“Our aluminum retrofit cut energy waste by 15%—paying for itself in 18 months.”

Small shops can DIY, but experts deliver guaranteed seals. Check warranties—some pipes include decade-long coverage.

Bringing It All Together

Safety outweighs sticker price in compressed-air piping. Older systems account for 92% of accidents due to degraded piping. Aluminum offers 99.8% reliability, making it a smart long-term choice.

Key takeaways:

- Avoid brittle materials that shatter under pressure.

- Metallic lines beat plastics on both safety and durability.

- Failing to comply can cost you big in fines and claims.

Ready to upgrade? Grab same-day pricing and deals on kits from Installation Parts Supply. Request your free template or emergency service today.

Make safety your piping priority—act today.