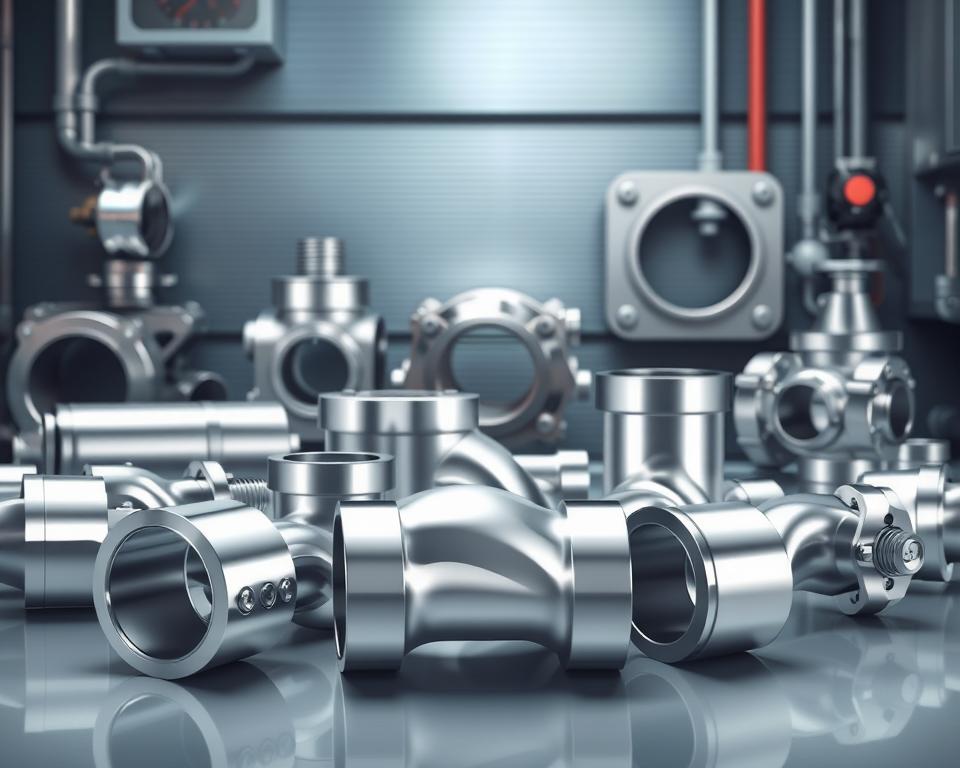

Advanced Tri-Clamp-Style Sterile Fittings for Maximum Cleanliness

Whenever sanitation is life-saving, even microscopic gaps pose a risk. Therefore, companies like Installation Parts Supply offer high-precision solutions created to mitigate threats. Their hygienic connection systems blend durability with tool-less construction, positioning them as a top choice for workplaces that demand perfection.

These parts aren’t just about eliminating leakage – they’re crafted for the stringent standards of food-grade production, drink-line facilities, and biopharma plants. Manufactured using corrosion-resistant materials, they endure repeated washdowns while retaining form. The conceptual approach parallels industry leaders like Alfa Laval, placing first sanitary pipe fittings smooth surfaces and rapid breakdown.

What sets these products apart? Think single-handed setup and wrench-free servicing. Line staff welcome the straightforward build during busy shifts, while team leads favor standardized performance across pipelines. Every piece is subjected to stringent QC to confirm conformity to FDA and 3-A Sanitary Standards.

Noteworthy Points

- Relied on by experts for airtight reliability in high-stakes contexts

- Fabricated in food-grade stainless steel for long-term resilience

- Simplifies compliance with food safety and pharmaceutical regulations

- Reduces downtime through snap-lock construction and cleaning

- Strengthened with testing programs matching global benchmarks

Overview & Primary Benefits

Leak-free unions are the backbone of sanitary production. Installation Parts Supply creates components that blend accurate craftsmanship with operational practicality. Their products ensure sealed reliability while simplifying maintenance workflows—critical for sectors where efficiency meets cleanliness.

High-Spec Construction & Cleanliness Benchmarks

Every piece is heavily tested to comply with worldwide norms. The materials withstand chemical attack, even after multiple CIP sequences. Leak-proof seals banish contamination, a feature hailed by dairy processors and pharmaceutical manufacturers alike.

These fittings mirror the standards of leaders like Alfa Laval, delivering smooth surfaces and uniform dimensions. Modular formats mesh with installed equipment, minimizing conversion fees. Workers note 30% faster fitment compared to traditional threaded systems.

Edge Provided by Installation Parts Supply

Tailor-made production distinguishes this company. Want an odd size or special coating? Their team partners closely with engineers to produce precise builds. Immediate dispatch and 24/7 technical support maintain uptime.

The perks extend beyond durability. No-tool breakdown shrinks pauses during sanitation audits. Liquid processing sites using these connectors experience fewer production stoppages and even output. It’s not just about meeting regulations—it’s about going beyond without strain.

Engineering Specs & Construction Details

Exact machining blends into modularity in today’s process plants. Installation Parts Supply builds components that unite exact measurements with versatile designs. Their philosophy secures frictionless compatibility into current lines while retaining rigorous sanitary rules.

Bespoke Metals & Finishes

No two projects are identical. That’s why materials range from 304 to 316L stainless steel, picked for strength and corrosion resistance. Surface treatments like electropolishing create mirror-like smoothness, diminishing biofilm formation by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes use laser metrology to verify uniform wall thickness. Narrow allowances (±0.005″) eliminate thin zones in pressure-heavy systems. During quality checks, components experience X-ray scans and pressure tests to detect microscopic flaws.

Tailoring extends beyond aesthetics. Clients demand specific angles, flange sizes, or purpose-built coatings for chemical resistance. These bespoke solutions help industries adhere to shifting standards without redesigning entire systems.

Tri Clamp Sanitary Fittings: Installation and Applications

Modern high-speed plants need fittings that fit fast yet perform reliably. These fitting packages stand out in environments where pace dovetails with cleanliness. Their design does away with heavy tooling, letting teams to focus on productivity rather than setup struggles.

Easy Installation Steps

Coupled flange rims and a centered gasket establish fail-safe closures in seconds. Staff position the parts, locate the squeeze band, and secure manually – no wrenches required. This process cuts fitting mistakes while keeping even compression across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Adaptable Links Between Systems

Connecting clean pipes to vessels, these interfaces mate assorted elements fluidly. The uniform design aligns with various diameters, supporting speedy swaps during product changeovers. Dairy plants regularly utilize them to alternate between cleaning cycles and production runs seamlessly.

Cleaning squads value how components come apart for thorough sanitation. Smooth surfaces prevent residue buildup, while the absence of threads avoids bacterial hideouts. Weekly cleanings need half the hours compared to older connection methods.

Sector Uses & Regulatory Alignment

Spanning artisan beer halls to inoculation plants, modern facilities use hardware that meet multiple objectives while complying with severe standards. Installation Parts Supply brings solutions used across key markets where product purity is essential. Their designs unite performance with rules, crafting assemblies that thrive under demand.

F&B plus Pharma Fields

Within drink and food factories, speedy-switch links simplify switching between recipes or cleaning cycles. Breweries rely on custom tees to manage complex flow paths with zero blend danger. Pharmaceutical manufacturers bank on leak-free closures to defend reactive substances during sterile transfers.

These units ship in assorted gauges to match piping layouts, from compact lab setups to large-scale fermentation tanks. Dairy processors value how standardized parts reduce downtime during equipment upgrades. Even minor tweaks in production processes are embraced through modular designs.

Adherence to ASME, ISO, and 3-A Guidelines

Every fitting achieves and goes beyond benchmarks set by global organizations. ASME-certified materials manage hot media in pasteurization systems, while ISO-compliant finishes prevent bacterial buildup. The 3-A symbol certifies compatibility for direct contact with consumables.

Tri-clover fittings embody this pledge. Their uniform dimensions guarantee tight sealing across automated lines. Third-party audits check sourcing from raw materials to finished goods, granting QC staff confidence.

By tracking these benchmarks, facilities ease compliance tasks and pass inspections effortlessly. It’s not just about avoiding fines—it’s about building consumer trust through obvious compliance.

Closing Thoughts & Action Plan

Selecting parts that pair output and rules drives facility results. Installation Parts Supply offers systems that merge toughness and cleanliness, ensuring leak-free performance across food, pharma, and beverage environments. Their products conform to rigorous standards while easing everyday operations through straightforward build.

With variants in steels and textures, solutions match individual line needs. Whether transporting heated slurries or frequent cleaning cycles, material choices and surface treatments enhance life cycle. Professionals value the wide selection of connection types matched to given flow speeds and psi loads.

Procurement stays smooth, with technical support ready to match equipment needs. Same-day shipping and agile help reduce production stalls during upgrades or replacements. Routine maintenance becomes effortless thanks to quick-release joints and glossy paths that block grime.

Ready to enhance your facility’s reliability? Get in touch with Installation Parts Supply to examine purpose-built arrangements – from sanitary clamp to tri-clover-style connectors – reinforced by premium QC. Their team secures code compliance today while readying plants for future regs.